Contact Us

Tel: 0086-512-52488753

E-mail:lilyzou@alpcs.com

Whatsapp:+86-13862319792

Whatsapp:+86-15150409031

Add:No.5 Xinlv Road, Xinzhuang Town, Changshu City, Jiangsu Province

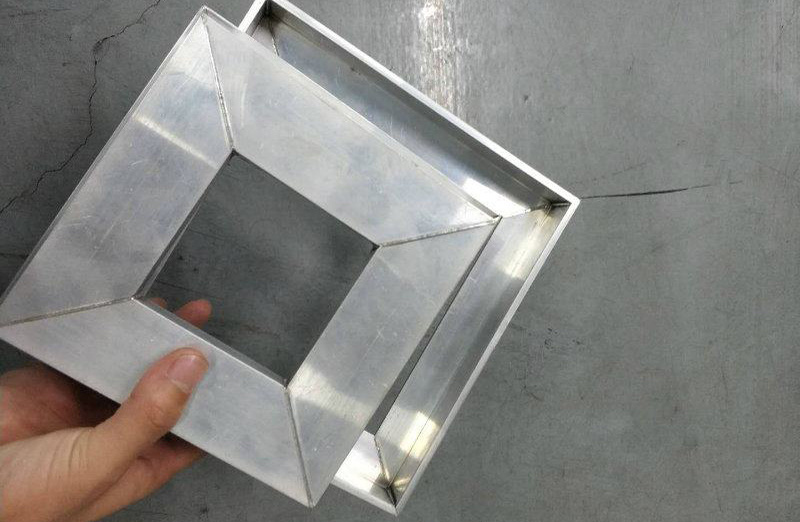

Laser Welding

Provide aluminum welding services for different products in different fields

Changsheng has 13 DVS qualified welders (EN ISO 9606-1) with over 20 years of experience. With these welders, we can handle most projects and provide perfect welding components. In order to maximize efficiency and cost-effectiveness, two welding robots (one TIG and one MIG) were used in production. Changsheng also offers laser welding. By providing high-quality welding services, we can meet the requirements of customers in different industries for various products

Compared to other welding techniques, using laser welding has some obvious advantages.

Speed and flexibility

Laser welding is a very fast technology. According to the type and power of the laser used, thin section materials can be welded at a speed of several meters per minute. Therefore, lasers are very suitable for working in high productivity automated environments. For thicker sections, productivity can also be improved because the laser keyhole welding process can complete one joint in one pass

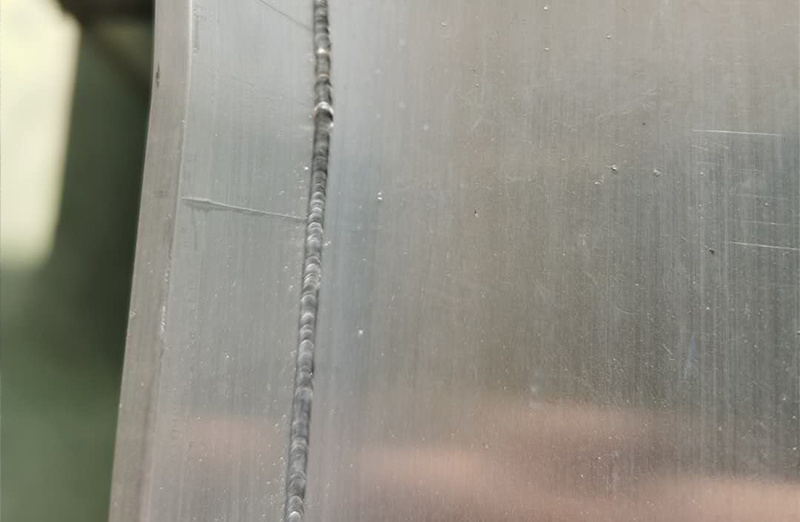

Deep narrow weld seam

Laser welding allows for welding with a high aspect ratio (large depth to narrow width). Therefore, laser welding is feasible for joint configurations that are not suitable for many other (conduction limited) welding techniques, such as pile welding through lap joints. Compared to parts manufactured using resistance spot welding, this allows for the use of smaller flanges.

Low distortion and low heat input

Laser generates a highly concentrated heat source that can generate a keyhole. Therefore, the volume of welding metal generated by laser welding is very small, only transferring limited heat to the surrounding material, so the deformation of the sample is smaller than that of samples welded using many other processes. Another advantage of this low heat input is that the width of the Heat-affected zone on both sides of the weld is narrow, thus reducing the thermal damage and property loss of the base metal near the weld.

Non contact single sided process

Laser welding does not apply any force to the connected workpiece, and is usually a single sided welding, which completes the connection from one side of the workpiece. However, like many other welding processes, it may be necessary to perform root shielding from the opposite side.

Discontinuous welding

Using laser, spot welding or seam welding, if applicable, can be carried out as easily as continuous welding.

Prev

Next