Contact Us

Tel: 0086-512-52488753

E-mail:lilyzou@alpcs.com

Whatsapp:+86-13862319792

Whatsapp:+86-15150409031

Add:No.5 Xinlv Road, Xinzhuang Town, Changshu City, Jiangsu Province

Powder coating

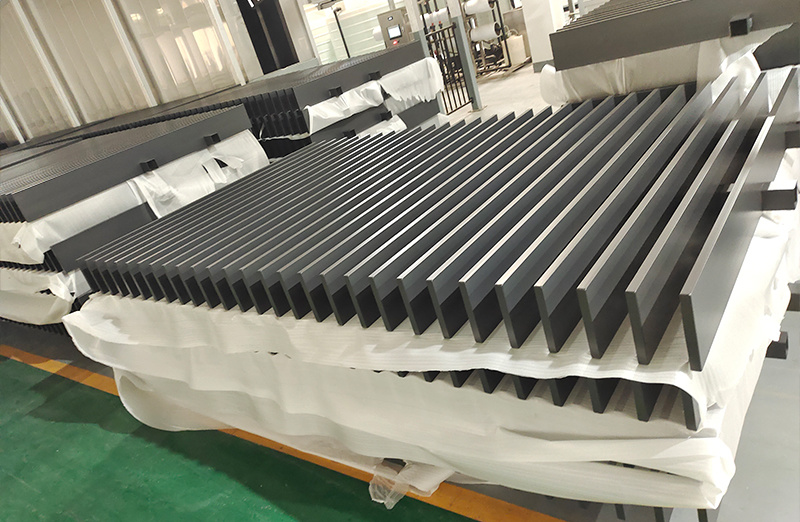

Changsheng began operating the powder spraying production line in 2003.

Changsheng began operating the powder spraying production line in 2003. Over the years, many products have been powder coated, such as railings, ladders, ramps, etc. In 2020, we invested over $400000 to build a new automatic powder spraying production line consisting of cleaning, drying, coating, and curing. The automation system has shortened production time and reduced labor costs. At the same time, it can also obtain better coatings and more consistent products. Therefore, it enables us to bring more competitive products to customers in the market

What is powder spraying? How does it work?

Powder spraying is a coating method for metal parts, which is significantly different from traditional coating methods. Its working method is to spray a certain color of powder onto the metal surface, which maintains an electric charge. Electric charge will cause the powder to adhere to the surface, and once the spraying is completed, the powder will be baked.

Advantages of powder spraying

Powder spraying has several advantages that have led many companies to use it. Several of the biggest benefits are extraordinary durability and lifespan. In addition, powder coatings can save companies money and help them raise environmental awareness

Learn more about the advantages of powder coatings:

1. Durability

If your parts are powder coated, they will be very wear-resistant no matter what purpose they are used for. This coating has resistance to fragmentation, fading, scratching, and wear. This durability makes it very suitable for metal parts exposed to sunlight and other environmental factors

Polyester powder coatings and other forms are often used for all parts from different industries to the outside or inside. With so much surface durability, you can expect your finish to remain intact for a long time.

Fading is a problem with paint, but powder coating can help slow down the fading and maintain the appearance of the parts in the coming years. UV resistant powder coating consistently protects the appearance of your product for a long period of time.

In addition to being a very durable finish, powder coating can also protect the underlying metal from damage. For example, rust is a major danger to metal parts, especially when the metal is exposed to outdoor air and moisture. The rust resistance of powder coatings is a very popular characteristic, especially in high-risk areas

2. Long life

If your parts are powder coated, they will be very wear-resistant no matter what purpose they are used for. This coating has resistance to fragmentation, fading, scratching, and wear. This durability makes it very suitable for metal parts exposed to sunlight and other environmental factors

Polyester powder coatings and other forms are often used for all parts from different industries to the outside or inside. With so much surface durability, you can expect your finish to remain intact for a long time.

Fading is a problem with paint, but powder coating can help slow down the fading and maintain the appearance of the parts in the coming years. UV resistant powder coating consistently protects the appearance of your product for a long period of time.

In addition to being a very durable finish, powder coating can also protect the underlying metal from damage. For example, rust is a major danger to metal parts, especially when the metal is exposed to outdoor air and moisture. The rust resistance of powder coatings is a very popular characteristic, especially in high-risk areas

3. Ecological friendliness

Most importantly, powder coating is a very environmentally friendly way of coloring metal parts. Although it is applied by spraying powder on the parts, the powder does not contain any chemical substances that cause it to adhere. It adheres to the metal through surface charges, so no solvents are used. Usually, dry powder enters the metal directly during spraying, and the powder entering the air is easy to clean.

Prev

Next