Contact Us

Tel: 0086-512-52488753

E-mail:lilyzou@alpcs.com

Whatsapp:+86-13862319792

Whatsapp:+86-15150409031

Add:No.5 Xinlv Road, Xinzhuang Town, Changshu City, Jiangsu Province

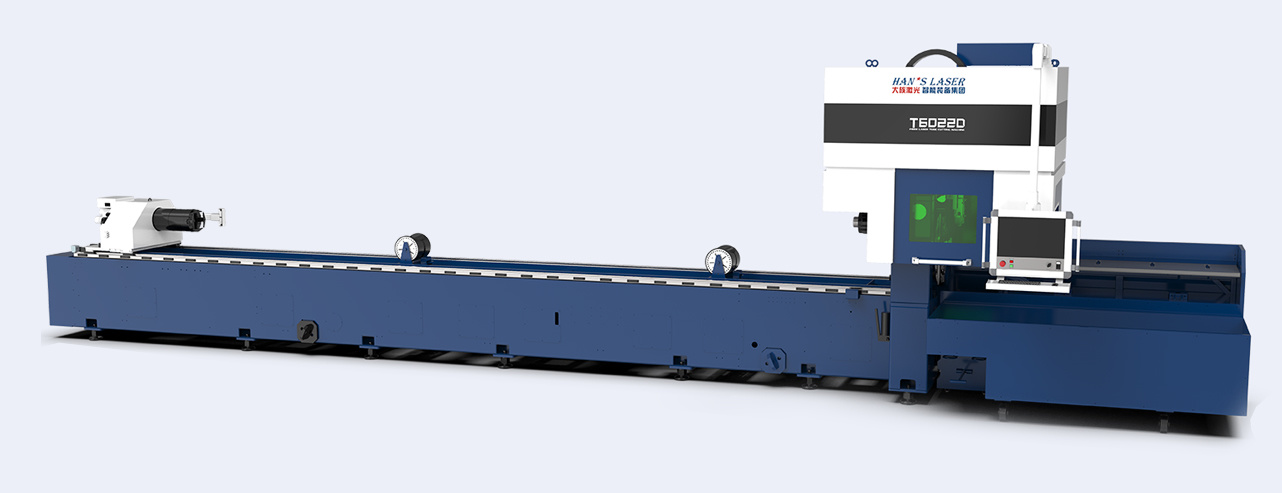

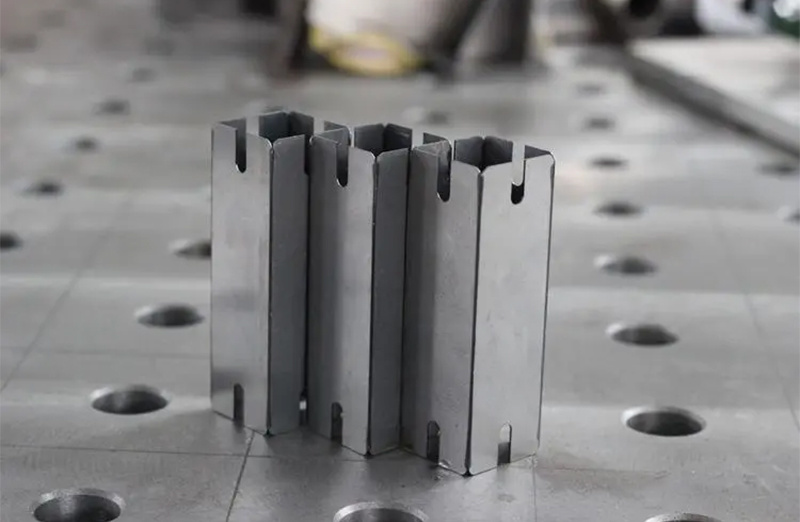

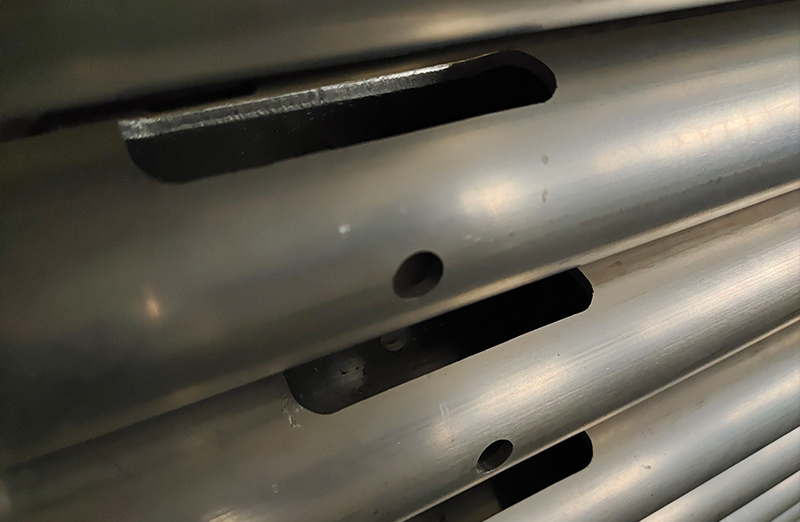

Laser cutting

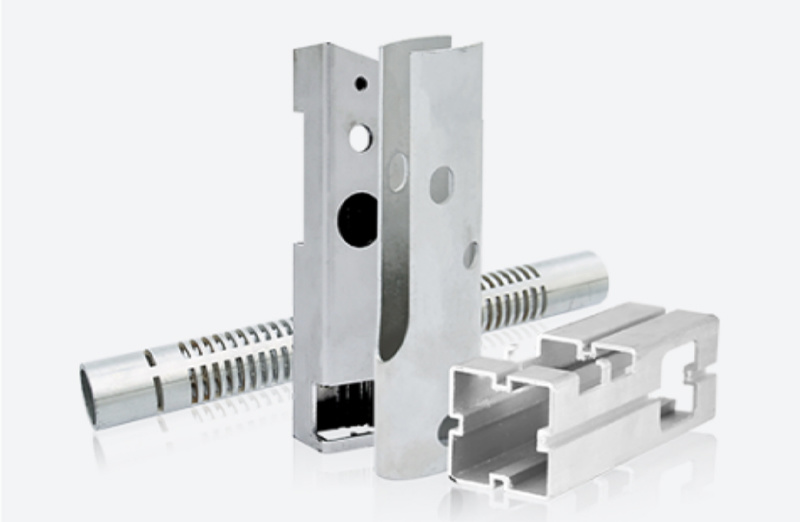

Provide precision aluminum processing services

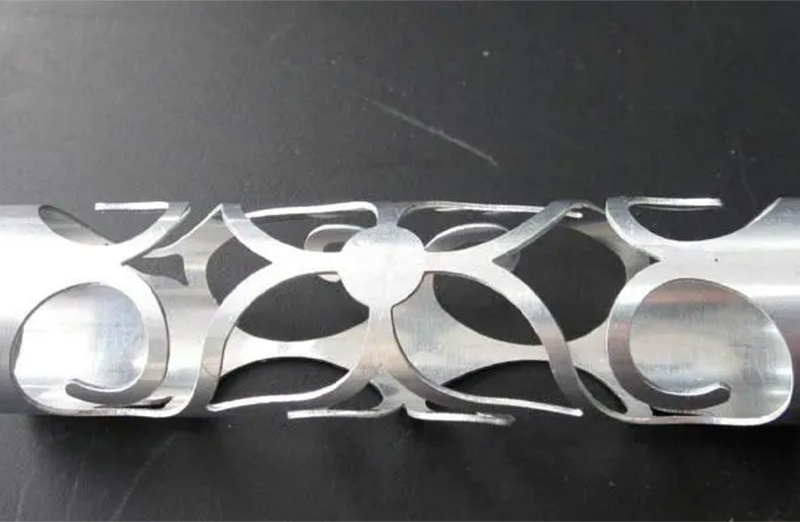

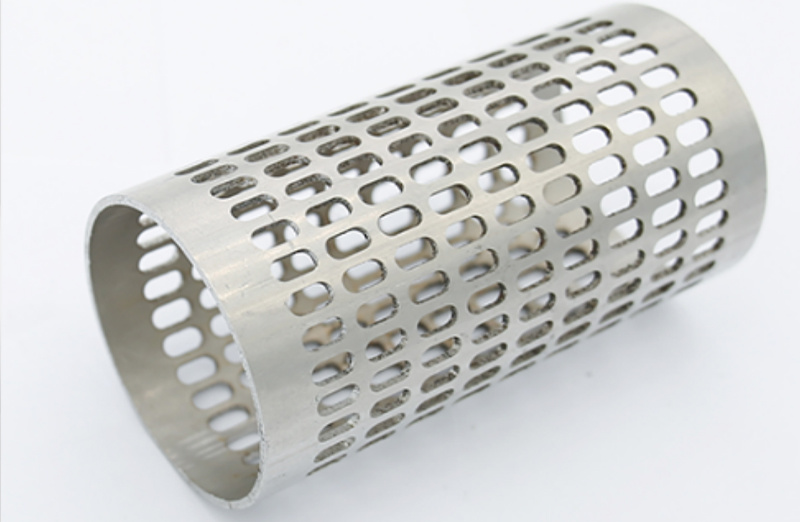

Traditional product processing parts usually use stamping method, resulting in high mold loss. Under the same conditions, the flexibility of laser processing is reflected.

Laser cutting is the use of a high-power density laser beam to irradiate the cut material, rapidly heating it to the gasification temperature and evaporating it to form pores. As the beam of light moves on the material, the holes continuously form very narrow (such as about 0.1mm) slits to complete the cutting of the material.

Laser cutting machine processing not only cuts narrow seams, has small deformation, high accuracy, fast speed, high efficiency, and low cost, but also avoids replacing molds or tools, shortening the production preparation time cycle. At the same time, it also has the advantages of fine cutting seam, small Heat-affected zone, good cutting surface quality, no noise when cutting, smooth cutting edge, easy to realize automatic control of the cutting process, etc.

Specification parameters

| Processing tube size range | Φ15-220mm □15-150mm |

| Maximum raw material length | 6750mm |

| Maximum cutting length | 4000mm |

| Maximum weight capacity | 150kg |

| X and Y axis speeds | 100m/min |

| A. Maximum speed of B-axis | 150r/min |

Prev

Next